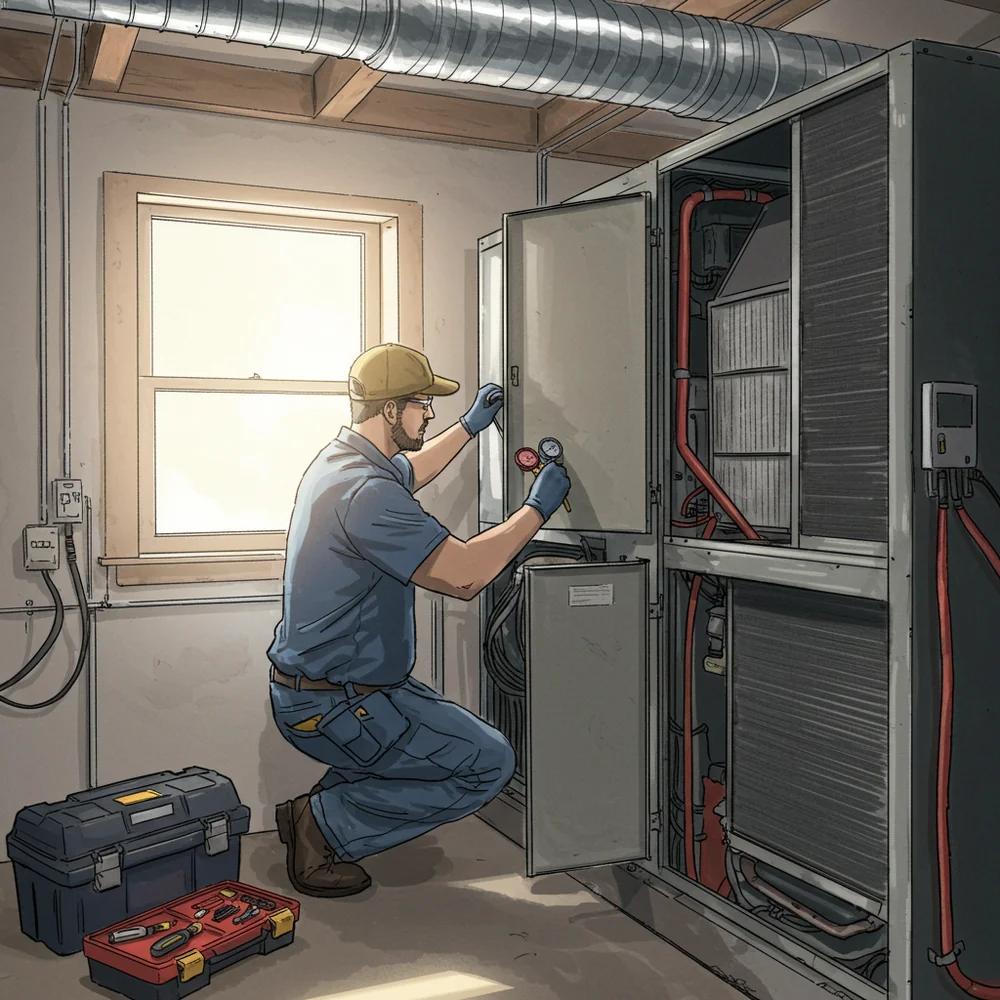

HVAC Maintenance Checklist: Prevent Breakdowns & Save Energy

HVAC Maintenance Checklist

Complete HVAC maintenance checklist covering all essential heating, ventilation, and air conditioning system components including safety procedures, filter maintenance, coil cleaning, refrigerant system checks, electrical controls, and performance testing for optimal system efficiency and longevity.

1. Safety & Pre-Inspection Checks

2. Air Filter & Airflow Management

3. Coils, Condenser, and Evaporator Components

4. Condensate Drains & Drainage System

5. Blower, Fans & Ductwork

6. Refrigerant System / Cooling Cycle

7. Electrical & Control Systems

8. Heating / Combustion / Heat Exchanger (for systems with heat)

9. Thermostat, Sensors & Controls

10. System Operation, Performance & Reporting

Overall Progress

0% complete

Checklist Progress

0% complete - Ready to download!

Related Checklists

Explore more checklists in the Maintenance Checklists category

AC Maintenance Checklist 2025: Stay Cool & Reduce Energy Bil

Comprehensive air conditioning maintenance checklist covering safety, filters, coils, electrical systems, refrigerant, and performance testing.

Preventive Maintenance Checklist for Safety & Compliance

Comprehensive preventive maintenance checklist covering safety, inspection, cleaning, lubrication, and system performance for equipment and facilities.

Furnace Maintenance Checklist: Safety, Efficiency & Reliability

Comprehensive furnace maintenance covering safety procedures, combustion systems, electrical components, and performance testing for optimal operation.

Fall Home Care Checklist to Prepare for Cold Weather

Comprehensive fall home maintenance checklist covering roof, gutters, heating systems, plumbing, electrical, and winter preparation tasks.

RV Maintenance Checklist for Reliable Trips

Comprehensive RV maintenance checklist covering engine, systems, safety, and seasonal care to keep your recreational vehicle road-ready.

Popular Categories

Most downloaded checklist categories

Audit Checklists

Ensure accuracy and compliance with audit checklists for business, finance, and safety. Organized tools for efficient auditing.

Assessment Checklists

Streamline evaluations with detailed assessment checklists. Ensure accuracy, consistency, and efficiency in academic, workplace, and project reviews.

Car Checklists

Find essential car checklists for maintenance, safety, road trips, and inspections. Stay prepared and keep your vehicle in top shape.

Home Checklists

Explore home checklists for cleaning, organization, safety, and maintenance. Keep your home efficient, safe, and clutter-free.

Planning Checklists

Get planning checklists for events, projects, and personal goals. Organize tasks and achieve success step by step.

Safety Checklists

Stay safe with checklists for workplace, home, and emergency preparedness. Reduce risks and stay ready for any situation.